In the dynamic world of signage and display, Foamex stands out as a versatile and cost-effective material. Foamex’s lightweight yet sturdy nature makes it a popular choice for indoor and outdoor use throughout the UK. This blog delves into the techniques that ensure vibrant and durable prints on Foamex, helping businesses and individuals make the most of this remarkable material.

Understanding Foamex

Foamex, the alternative name for PVC foam board, is a durable, rigid plastic sheet formed from expanded PVC. The smooth surface of Foamex enables high-quality printing, making it an excellent choice for signage, exhibition panels, and promotional displays. With options in 3mm, 5mm, and 10mm thicknesses, Foamex caters to a wide range of uses, from indoor signage to tough outdoor boards.

Techniques for Vibrant Prints

Achieving vibrant prints on Foamex involves several key techniques:

1. UV Printing

UV printing ensures the production of vibrant, high-quality images on Foamex, making it the preferred choice. This technique uses ultraviolet light to cure the ink instantly, resulting in prints that are resistant to fading and scratching. UV printing works well for both indoor and outdoor settings, preserving colour integrity and longevity.

2. High-Resolution Artwork

For optimal print quality, ensure the use of high-resolution artwork. To ensure clarity and precision, a 300 dpi (dots per inch) resolution is recommended. This level of detail is particularly important for large-format prints, where image clarity can significantly impact visual appeal.

3. Colour Management

Implementing proper colour management ensures that the printed colours match the intended design. Using colour profiles like CMYK and calibrating monitors can help maintain colour consistency across different devices and print outputs.

Enhancing the Longevity of Foamex Signage: Best Practices

While Foamex is inherently durable, certain practices can extend its lifespan:

1. Lamination

Applying a laminate layer—available in matte, gloss, or dry-wipe finishes—adds a protective coating to the print. Lamination guards against UV rays, moisture, and physical wear, making it especially beneficial for outdoor signage.

2. Proper Mounting

Secure mounting prevents warping and damage. For indoor displays, Velcro strips or adhesive pads suffice, while outdoor signs may require screws or standoffs. Ensuring the mounting method suits the environment enhances the sign’s stability and longevity.

3. Edge Sealing

Sealing the edges of Foamex boards can prevent moisture ingress, which is crucial for outdoor applications. Edge sealing involves applying a waterproof coating or tape to the board’s sides, offering additional protection against the elements.

Applications in the UK Market

Due to its versatility, Foamex is widely used across different industries throughout the UK.

- Retail Signage: Stores utilise Foamex for promotional signs, point-of-sale displays, and directional signage due to its professional finish and durability.

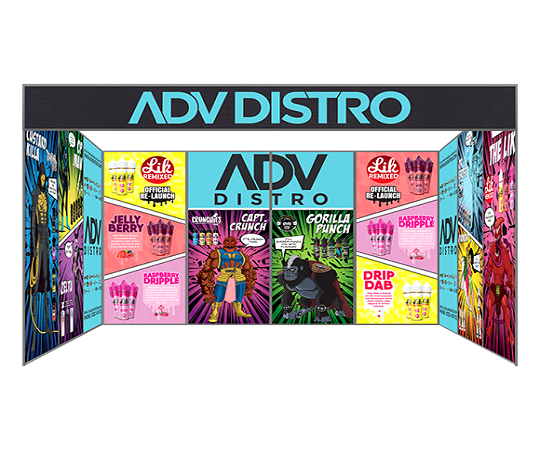

- Exhibitions and Trade Shows: Exhibitors prefer Foamex for its lightweight nature, ease of transport, and high-quality print capabilities, making it ideal for display panels and backdrops.

- Construction Sites: Foamex boards serve as site safety signs and informational displays, withstanding outdoor conditions effectively.

- Educational Institutions: Schools and universities use Foamex for notice boards, event signage, and informational displays, benefiting from its ease of installation and maintenance.

Environmental Considerations

While Foamex is not recyclable through standard municipal systems, many UK printing companies are adopting sustainable practices:

- Recycling Programs: Some offer take-back schemes, collecting used Foamex boards for recycling through specialised channels.

- Eco-Friendly Alternatives: Materials like Bubble Board and Correx are gaining popularity as recyclable alternatives for short-term signage needs.

- Sustainable Printing Practices: The UK printing industry is increasingly embracing eco-friendly inks and energy-efficient processes, contributing to a more sustainable future.

Why Foamex Printing is Gaining Popularity in the UK

The demand for Foamex printing in the UK reflects its effectiveness as a signage solution:

- Cost-Effectiveness: Foamex offers a balance between quality and affordability, making it accessible for businesses of all sizes.

- Customisation: Advancements in printing technology allow for intricate designs and custom shapes, catering to diverse branding needs.

- Quick Turnaround: Many UK printers provide same-day or next-day services, accommodating tight deadlines and last-minute requirements.

Conclusion

Foamex stands as a reliable and versatile material for vibrant and durable signage. By employing techniques like UV printing, high-resolution artwork, and protective lamination, businesses can create impactful displays that withstand the test of time. As the UK market continues to value cost-effective and high-quality signage solutions, Foamex remains a top choice for various applications.

Karishma

An enthusiastic Graphic Designer professional with strong communication and organisational skills, who is passionate about creating and developing innovative ideas with the client to help them get their business noticed. I work to the highest standards and have an excellent eye for detail with skills in design and organisation. I am a dependable and productive worker whose honesty and integrity provides effective leadership and builds excellent relationships. I enjoy innovatively…

Apr 18 2025

Leading

Print Technology

We only invest in the latest print and finishing equipment